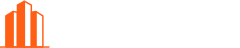

Filter wire mesh is a specialized type of mesh designed specifically for filtration applications across various industries. It is made from different metals, with stainless steel being the most common due to its durability and resistance to corrosion. This mesh is designed to separate, sift, and filter contaminants and particles from liquids, gases, or solids.

Weave

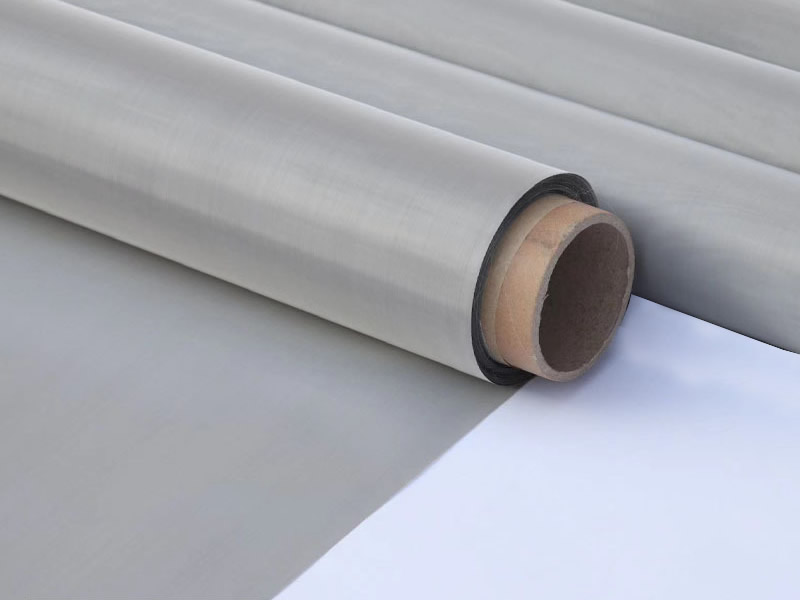

- Plain Weave: Each wire alternately crosses over and under the next wire. This weave is ideal for general filtering in water treatment and air filtration due to its uniform openings and stability.

- Twill Weave: Each wire passes over and under two wires in a staggered fashion, creating a diagonal pattern. This weave is beneficial for finer filtration needs, such as in high-pressure fluid applications and the pharmaceutical industry.

- Dutch Weave: This weave features a tight mesh with more wires in one direction and finer wires in the other, resulting in smaller openings. It is excellent for fine filtration tasks in the chemical and petrochemical industries.

- Reverse Dutch Weave: The opposite of a Dutch weave, this style uses fewer, thicker wires in one direction and more, thinner wires in the other. It is suitable for plastic extrusion and other applications requiring fine mesh with high strength.

- Twilled Dutch Weave: A combination of twill and Dutch weaves, uses two wires in an over-and-under pattern to create a fine mesh. It is used in high-pressure filtration and for filtering very fine particles in the oil and gas and aerospace industries.

Type

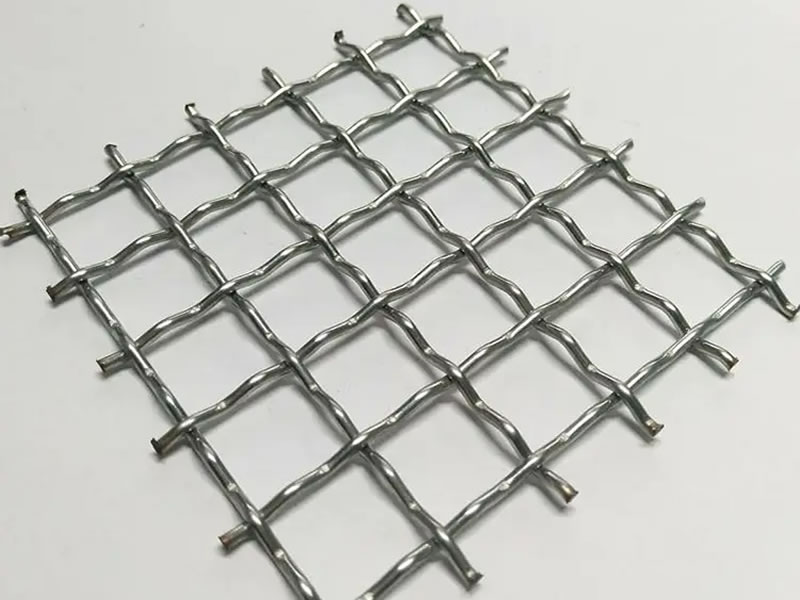

- Stainless Steel Wire Mesh Filters: Made from woven or welded stainless steel wire mesh, can vary in weave tightness and wire thickness. Used in applications ranging from industrial filtration systems, automotive, aerospace, and food and beverage processing to residential HVAC systems.

- Sintered Filter: Made by fusing metal particles together at high temperatures to form a porous, yet strong filter. These filters offer excellent strength and resistance to pressure and temperature. They are used in high-pressure and high-temperature environments, such as in aerospace, chemical processing, and hydraulic systems.

- Cartridge Filters: Consist of a cylindrical housing that encloses a replaceable filter cartridge, often made from stainless steel mesh or fibers. Commonly used in fluid processing, including water treatment, chemicals, and oils, where easy maintenance and reliability are needed.

- Pleated Filters: Feature pleated filter media to increase surface area and filtration efficiency. Used in high-flow rate environments that require fine filtration with minimal pressure drop, such as pharmaceutical manufacturing, food processing, and air purification.

- Basket Filters: Include a basket-shaped strainer inside a housing, designed to be cleaned and reused. Often found in pipeline systems to protect pumps, valves, and other process equipment from contaminants.

- Mesh Conical Strainers: These are cone-shaped filters made of metal mesh designed to catch debris in a flowing system. The conical shape allows for easy cleaning and efficient filtration. They are ideal for use in pipelines and plumbing systems to prevent blockage from debris.

- Stainless Steel Disk Filters: These are made from layers of stainless steel mesh welded into disk-shaped elements. They effectively remove particles from liquids and air, and can be stacked to increase filtration efficiency. Commonly used in the pharmaceutical, chemical, and food processing industries for precise filtration.

- Extruder Screen Mesh Cylinders: These cylindrical screens are made from woven wire mesh, designed to fit inside extruder heads. The screens help filter out contaminants and irregular particles from plastic and rubber during the extrusion process. They are used in the polymer and plastic manufacturing industry to ensure product purity and consistency.

- Beer Filter Screen Mesh: Specialized filters designed for brewing applications. These screens help remove sediments and ensure clarity by filtering hops, grains, and other solids during the beer brewing process. They are used in both commercial breweries and home brewing setups to maintain the quality and taste of beer.

- Filter Mesh Caps: These caps are made of wire mesh and fit over the end of a pipe or tube to filter out contaminants. They provide an easy way to add a filtering element to existing systems. They are widely used in automotive, industrial, and agricultural settings for simple and effective filtration.

- Perforated Filter: Tubes made from metal that is perforated with holes covered by mesh, designed to filter out larger particles while allowing fluids to flow through. Common in oil and gas, water treatment, and industrial manufacturing where robust, large-scale filtration is needed.

Features

- Heat Resistance: These filters can withstand high temperatures, making them ideal for applications involving hot fluids or environments.

- Chemical Resistance: The inherent properties of stainless steel allow it to resist various chemicals, ensuring that the filters maintain their integrity and functionality in chemical processing environments.

- Efficiency: Filters are designed to capture a wide range of particulates and contaminants, ensuring high levels of purity and efficiency in various applications.

- Adaptability: Modern filters are tailored to specific industrial needs, ranging from coarse to ultra-fine filtration, accommodating different pressures and temperatures.

- Durability: Made from robust materials, filters withstand harsh operational environments, contributing to long service life and reduced maintenance.

- Precision: High-precision manufacturing allows filters to achieve exact specifications for pore size and filtration capacity, crucial for applications in sensitive environments.

- Hygiene: Stainless steel is easy to clean and sterilize, preventing bacterial growth and making it perfect for sanitary applications such as food processing and pharmaceuticals.

- Versatility: Available in various grades and configurations, stainless steel filters can be tailored to meet specific needs, from fine to coarse filtration.

Applications

- Catalyst Recovery in Petrochemical/Chemical Industries: Filters retrieve valuable catalysts used in chemical reactions, reducing costs and environmental impact.

- Polymer Filtration: Essential in the polymer manufacturing process to remove impurities and ensure the quality of plastics and synthetic fibers.

- Cross Flow Filtration: Utilized in beverage production and pharmaceuticals for clarifying liquids without depleting the product.

- Gas Filtration: Critical in processing and handling gases in industries such as biotech, pharmaceuticals, and manufacturing to remove contaminants.

- Analytical Devices: Filters in devices like chromatographs and mass spectrometers ensure accurate and precise analytical results.

- Medical Devices: Used in life-supporting and surgical equipment, ensuring sterility and preventing contamination.

- Oil Filtration: Essential in automotive and industrial settings to maintain machinery efficiency and prolong equipment life.

- Gas-Liquid Separation: Separates gases from liquids in chemical processing and fermentation industries, enhancing product quality and consistency.

- Hot Gas Filtration: Filters withstand high temperatures in metal processing and power generation, removing particulates from exhaust gases.

- Fuel & Hydraulic Oil Filtration: Ensures the reliability of hydraulic systems and engines by removing impurities from fuels and lubricating oils.