Stainless steel wire mesh, made from durable and corrosion-resistant stainless steel alloys such as 304, 316, or 316L, is used in a variety of applications. It comes in different mesh sizes and wire gauges, making it suitable for everything from industrial filtration and architectural features to food processing and security barriers. Its strength and ability to withstand harsh conditions make it ideal for both indoor and outdoor uses across multiple industries.

Material

- 304: Commonly used for its excellent resistance to corrosion and oxidation across various environments.

- 304L: A lower carbon version of 304, offering similar resistance with improved weldability and lower post-weld corrosion risk.

- 316: Includes molybdenum, enhancing chemical resistance, especially against solvents and in marine settings. Preferred for harsher environments.

- 316L: The low carbon form of 316, suitable for large welds to lower carbide precipitation risk.

- 310: Known for high-temperature resistance, ideal for heat treatments and high-temperature applications.

- 430: A budget-friendly ferritic steel, suitable for less corrosive applications.

- 317/317L: Molybdenum-enhanced for even better corrosion resistance than 316/316L, especially against acids.

- 321: Adds titanium to 304’s composition for stability at high temperatures, up to 900°C.

- 347: Stabilized with niobium and tantalum for use in high temperatures without chromium carbide formation.

- 309: Has higher corrosion and heat resistance than 304, used in furnace parts and heat exchangers.

- 410: A heat-treatable martensitic steel offering good strength and moderate corrosion resistance.

- 2205 Duplex: A strong duplex steel with excellent corrosion resistance, ideal for corrosive environments.

- 2507 Super Duplex: Superior in strength and corrosion resistance to 2205, for demanding conditions.

- 904L: A high-alloy, low carbon steel for severe corrosion environments, highly resistant to acid.

- 330: Provides great resistance to high-temperature oxidation and carburization, perfect for furnace and heat treatments.

- 410S: A less hardenable version of 410, with improved weldability and corrosion resistance.

Weaving Methods

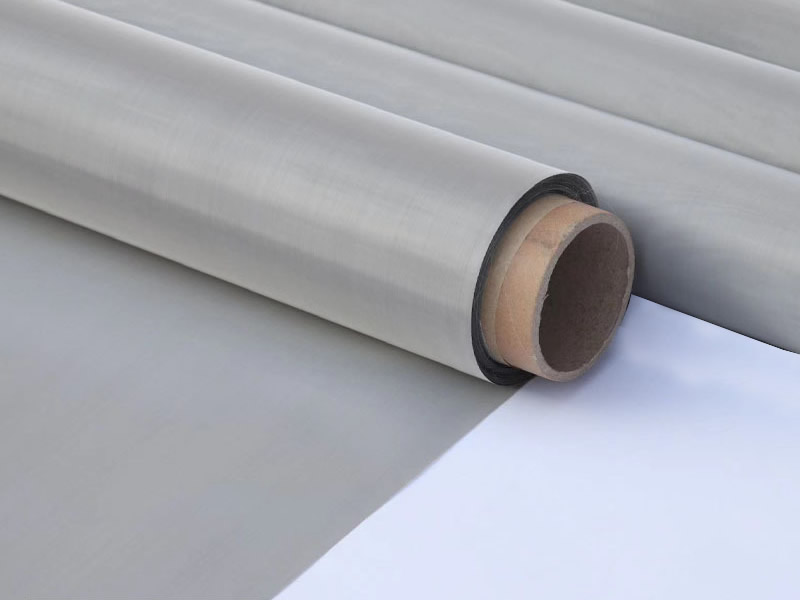

- Plain Weave: Simplest form where warp and weft wires cross each other alternately, creating a mesh suitable for various filtering tasks due to its uniform wire size.

- Twill Weave: Weft or warp wires cross over and under two adjacent wires in a pattern, allowing for denser and stronger mesh. Ideal for fine filtration under higher pressure and thicker materials.

- Dutch Weave: A plain weave variant using thicker warp wires and thinner weft wires, producing a fine mesh on one side and coarse on the other. Excellently supports high flow rates and finer filtration.

- Twill Dutch Weave: Merges twill and Dutch weaves for even tighter filtration, perfect for precise separation needs in industries like chemicals and pharmaceuticals.

- Reverse Dutch Weave: Features closer and tighter weft wires compared to warp wires, creating a strong mesh for fine, high-precision filtration in demanding applications.

- Five Heddle Weave: Offers a smooth surface on one side and rough on the other, enhancing flow and filtration efficiency. Commonly used in pressure and vacuum filters for improved filtering rates.

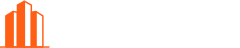

Stainless Steel Wire Mesh Rolls

- Flexibility: Rolls offer ease of handling and on-site size customization, enhancing suitability for diverse installation needs.

Storage and Transport: Roll form facilitates easier storage and transport, particularly for large quantities or sizes.

Continuous Length: The continuous, join-free lengths are advantageous for projects requiring uninterrupted sections of mesh.

Ideal for flexible and adaptable needs like fencing, garden netting, or as a plaster base in construction.

Used in customizable filtration systems, allowing adjustments directly on the installation site.

Suitable for agricultural uses, such as bird protection nets or windbreaks, where variable lengths are beneficial.

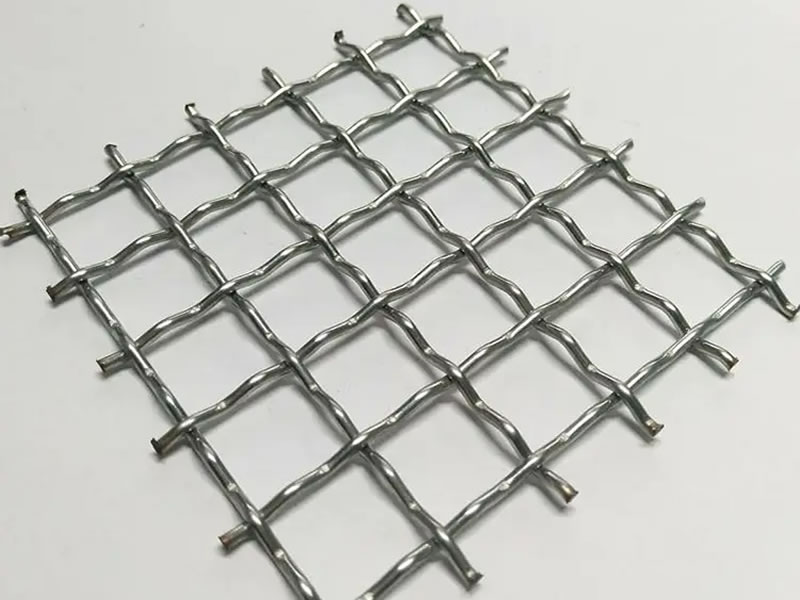

Stainless Steel Wire Mesh Panels

- Rigidity and Stability: The firmness and dimensional stability of panels support applications requiring structural integrity.

Precision: Pre-cut to precise dimensions for uniformity and accuracy, crucial where exact sizing is necessary.

Ease of Installation: Predetermined shapes and sizes simplify installation, especially when the mesh directly meets application specifications.

Optimal for architectural uses, including facades, partitions, and security screens, where structural aesthetics are key.

Employed in industrial environments for machine guards, ventilation screens, or stable filter assemblies, where durability is essential.

Perfect for construction and infrastructure, such as concrete reinforcement or railing infills, demanding high strength and specific dimensions.

Mesh Counts

The mesh count, or the number of openings per linear inch, varies widely to suit different filtering, screening, and protective applications. The range spans from very fine 500 mesh (for precise filtration needs) down to more open weaves like 2 or 4 mesh (for coarser applications), accommodating a broad spectrum of requirements.

- 2 to 10 Mesh: Coarse Grade: Mesh counts in the range of 2 to 10 represent the coarsest grades of stainless steel wire mesh. These low mesh counts mean larger openings between the wires, making the mesh ideal for applications requiring high flow rates, such as in certain filtration systems, protection barriers, and for agricultural uses. The wire diameters for these mesh counts are typically thicker to maintain structural integrity despite the larger openings, ensuring durability and strength.

- 20 to 60 Mesh: Medium Grade: Mesh counts from 20 to 60 fall into the medium grade category. This range offers a balance between strength and filtration capability, making it suitable for a wide array of applications including medium-fine filtration, ventilation, and pest control. The openings are smaller compared to the coarse grade, providing better filtration while still allowing for good airflow and light penetration.

- 80 to 200 Mesh: Fine Grade: The 80 to 200 mesh count range represents fine-grade stainless steel wire mesh. This category is characterized by smaller openings that provide excellent filtration for finer particles. It’s commonly used in industrial applications for filtering liquids and gases, in the food and beverage industry for straining and sieving, and in scientific laboratories for various separation processes. The wire diameter is thinner in this range, which helps in achieving the finer openings needed for precise filtration.

- 250 to 500 Mesh: Ultra-Fine Grade: Mesh counts ranging from 250 to 500 denote the ultra-fine grade of stainless steel wire mesh. This range is at the extreme end of fineness, with very small openings that are used for highly specific and critical filtering, sieving, and particle separation tasks. These ultra-fine meshes are essential in applications such as pharmaceutical manufacturing, fine chemical filtration, and in aerospace for various high-precision filtration requirements. The wire used in these meshes is extremely thin, enabling the production of a mesh that can filter very small particles while maintaining a high level of precision and consistency.

Wire Diameter

The wire diameters used in stainless steel mesh range from the ultra-fine 0.001 inches (0.025 mm) to a robust 0.250 inches (6.35 mm). This broad spectrum of wire thickness accommodates specific needs for strength, flexibility, and durability across various applications.

- 0.001 to 0.010 Inches (0.025 to 0.254 mm): Ultra-Fine Wire

In this ultra-fine range, the wire is ideal for high-precision filtering applications necessary in electronics, pharmaceuticals, and laboratory research. It allows for detailed separation processes with minimal obstruction, ensuring accuracy and efficiency. - 0.011 to 0.030 Inches (0.279 to 0.762 mm): Fine Wire

Fine wires, balancing strength with precision, are optimal for a variety of filtration and sieving tasks. This includes food processing, air quality management systems, and automotive fluid filtration, where reliability and precision are key. - 0.031 to 0.080 Inches (0.787 to 2.032 mm): Medium Wire

Medium wire diameters are suited for applications requiring a blend of strength and functional filtration. This includes industrial screening, architectural elements, and construction reinforcement, providing a durable solution for more demanding environments. - 0.081 to 0.250 Inches (2.057 to 6.35 mm): Heavy-Duty Wire

The thickest in the range, heavy-duty wire, addresses the needs of the most strenuous applications. Used in industrial barriers, high-stress filtration, and structural supports, it guarantees the highest level of durability and capability to withstand substantial loads.

Sizs

- 36 to 48 Inches Wide Rolls: Stainless steel wire mesh rolls are commonly available in widths ranging from 36 inches (approximately 91 cm) to 48 inches (approximately 122 cm). These dimensions are ideal for a variety of applications, providing adequate coverage for both industrial and residential uses. Lengths of these rolls can extend up to 100 feet (approximately 30 meters), catering to extensive coverage requirements without the need for joins.

- Up to 60 Inches and Beyond: For projects requiring even wider coverage, stainless steel wire mesh is available in widths up to 60 inches (approximately 152 cm) and, in specialized cases, beyond. This flexibility ensures that larger areas can be accommodated, making it suitable for expansive industrial applications or large architectural projects.

- Custom Lengths and Panels: 12×12 to 48×96 Inches: Customization allows for stainless steel wire mesh to be tailored to specific projects, with the ability to cut rolls into lengths beyond the standard or to precise dimensions. Panels, for instance, can be customized to sizes ranging from small 12×12 inch pieces (approximately 30×30 cm) to large 48×96 inch sheets (approximately 122×244 cm), fulfilling a wide range of application specifications from architectural designs to specific industrial uses.

Stainless steel wire mesh rolls offer flexibility and ease of use, making them suitable for applications from industrial filtering to residential gardening. They can be conveniently cut to size on-site for custom needs.

Securely packaged stainless steel wire mesh ensures that the product reaches the customer in pristine condition, free from damage and ready for immediate application, whether it be in construction, agriculture, or manufacturing.

Stainless steel wire mesh, available in varieties like SUS 304 and SUS 316, features different weave patterns and mesh counts, showcasing its adaptability. Each type has unique properties, making it suitable for specific applications.