Stainless steel wire rope is a type of cable made from strands of stainless steel wires twisted or braided together to form a highly durable and flexible rope. This rope is crafted from stainless steel, renowned for its resistance to corrosion and rust, making it ideal for use in harsh or marine environments. The most common materials used are grades 304 and 316, with 316 offering higher corrosion resistance and being preferred for marine applications.

Materials

- 304 Stainless Steel: Good overall strength and corrosion resistance. It’s suitable for a wide range of environments but less ideal for highly corrosive settings.

- 316 Stainless Steel: Offers excellent corrosion resistance, making it ideal for marine and harsh environments due to its superior resistance to salt and chemicals.

- 316L Stainless Steel: Similar to 316 but with lower carbon content, which helps minimize the risk of corrosion from welding. This grade is excellent for welded structures, especially in marine environments.

Wire Diameter

The thickness of individual cables, usually ranging from 1mm to 4mm (0.039 to 0.157 inches), which determines the strength and flexibility of the mesh.

Common Configurations

- 7×7 (also known as 6×7+FC): This configuration consists of six strands of seven wires each, around a fiber core. It offers a good balance between flexibility and resistance to abrasion and is suitable for use in pulleys and rigging.

- 7×19 (also known as 6×19+FC): Made up of six strands of 19 wires each, also around a fiber core, this type is highly flexible and ideal for dynamic load applications like cranes and hoists.

- 1×19: Consists of a single strand with nineteen wires. Very stiff and has a smooth surface, making it ideal for straight line applications where little bending is required, such as rigging, mast stays, and architectural uses.

- 6×36: Made up of six strands, each containing thirty-six wires. Offers a good balance between abrasion resistance and flexibility, making it suitable for bending over pulleys and winches in hoisting and towing applications.

- 8×19: Consists of eight strands, each with nineteen wires. Provides increased flexibility over the 6×19 construction, used for hoisting applications where the wire rope needs to bend frequently.

- 19×7: Nineteen strands, each with seven wires. A non-rotating rope type that is particularly useful in crane applications, where the load must not spin under the wire rope.

- 6×25: Features six strands, each composed of twenty-five wires. It strikes a balance between flexibility and wear resistance, suitable for varied mechanical applications where both properties are valued.

- 18×7 and 17×7: Composed of either eighteen or seventeen strands, each with seven wires. These are rotation-resistant ropes, slightly less stiff than 19×7, ideal for hoisting applications where rotation of the load can be a problem.

Tensile Strength

The tensile strength of stainless steel wire ropes can vary, with common specifications including 1570 N/mm2, 1770 N/mm2, and 1960 N/mm2. Higher tensile strengths are chosen for heavier loads and more demanding applications.

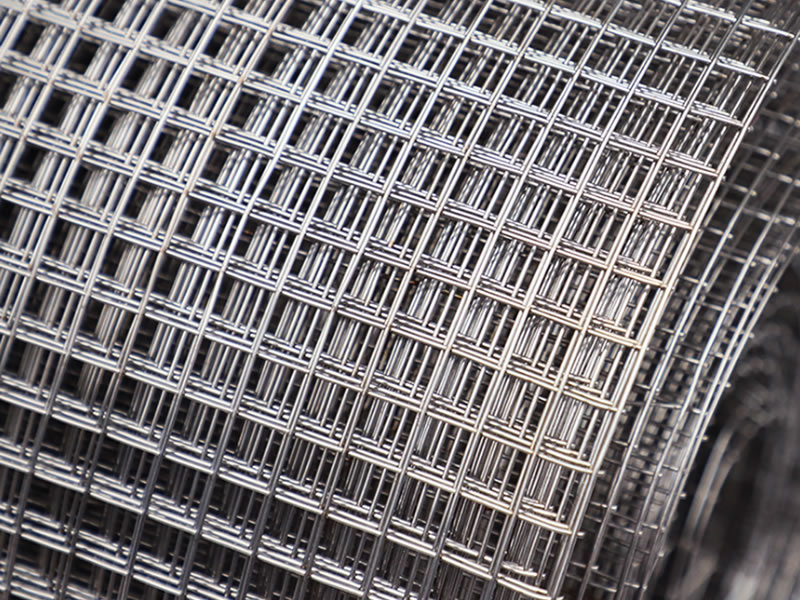

Standard Lengths

Reels and Coils: Stainless steel wire rope is typically supplied on wooden reels or in coils, with lengths depending on the diameter and the specific requirements of the project.

Steel Rope Fittings

- Thimbles: Protect the rope from wear by providing a durable loop.

- Clamps: U-bolt, fist grip, and double saddle, used to secure the rope end.

- Swage Fittings: Permanently attach to the rope by compression for a strong, sleek finish.

- Sleeves and Stops: Create loops or limit rope movement by crimping onto the rope.

- Shackles Types: D-shackles and bow shackles, connect the rope to other rigging hardware.

- Hooks: Facilitate lifting and towing, available with or without safety latches.

- Turnbuckles: Adjust rope tension or length through threaded ends.

- Eye Bolts and Nuts: Secure ropes to surfaces, providing an anchoring point.

Features

- Durability: Stainless steel wire rope is highly durable due to its resistance to rust and corrosion. This makes it suitable for long-term use in harsh environments without significant degradation.

- Strength: Known for its high tensile strength, stainless steel wire rope can handle heavy loads and high stress, making it ideal for demanding lifting and rigging tasks.

- Flexibility: Depending on the construction (e.g., 7×19), stainless steel wire rope offers excellent flexibility, which is crucial for applications requiring the rope to maneuver around pulleys and tight bends.

- Non-Magnetic: Some grades of stainless steel, like 304, are non-magnetic, which is essential for applications where magnetic interference could be a problem.

Applications

- Marine Use: Its corrosion resistance makes stainless steel wire rope perfect for marine applications, including mooring lines, rigging, and deck rails.

- Architectural: Often used in architectural applications for structural supports, balustrades, and aesthetic features due to its clean and modern look.

- Industrial: In industrial settings, it’s commonly used for lifting, hoisting, and securing heavy loads, thanks to its strength and durability.

- Aerospace and Automotive: Employed in the aerospace and automotive industries for applications requiring high strength-to-weight ratios and reliability under dynamic stresses.

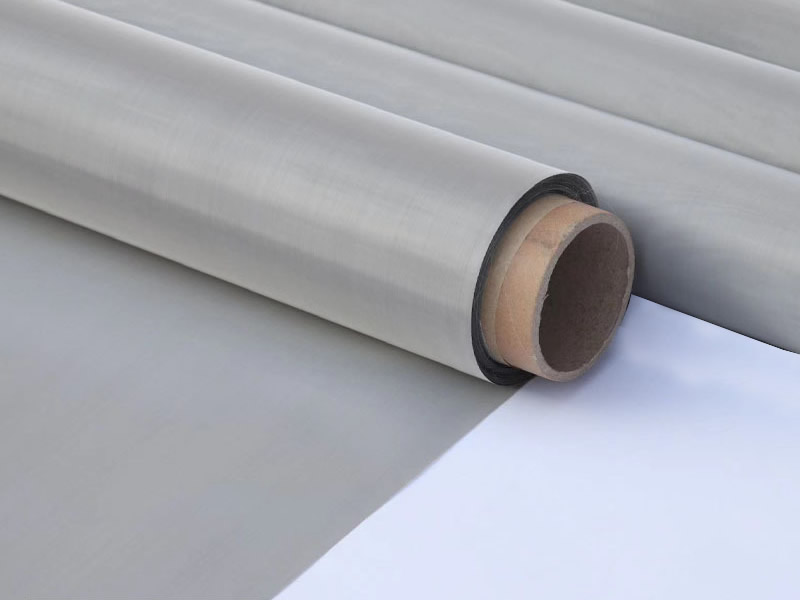

Stainless Steel Cable Mesh Specifications

- Ferruled Cable Mesh

Diameter: Ranges from 1.5 mm to 4 mm (0.059 inches to 0.157 inches).

Aperture Size: From 20×20 mm to 200×200 mm (0.79×0.79 inches to 7.87×7.87 inches).

Material: Available in stainless steel grades 304 or 316, with 316 for higher corrosion resistance.

Flexibility and Strength: Highly flexible, suitable for various structural applications with high tensile strength.

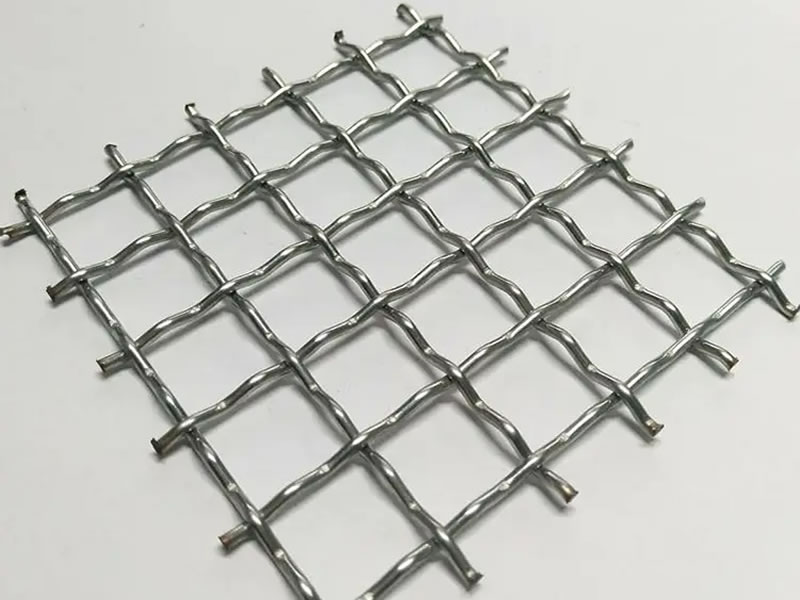

Visual Appeal: Sleek and modern, ideal for architectural uses. - Knotted Cable Mesh

Diameter: Typically from 1 mm to 4 mm (0.039 inches to 0.157 inches).

Aperture Size: Ranges from 25×25 mm to 200×200 mm (0.98×0.98 inches to 7.87×7.87 inches).

Material: Made from stainless steel grades 304 or 316, with 316 preferred in harsh environments.

Strength: Very durable, designed to withstand environmental stress.

Aesthetic: Offers a traditional look while providing robust security features.