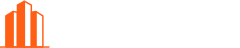

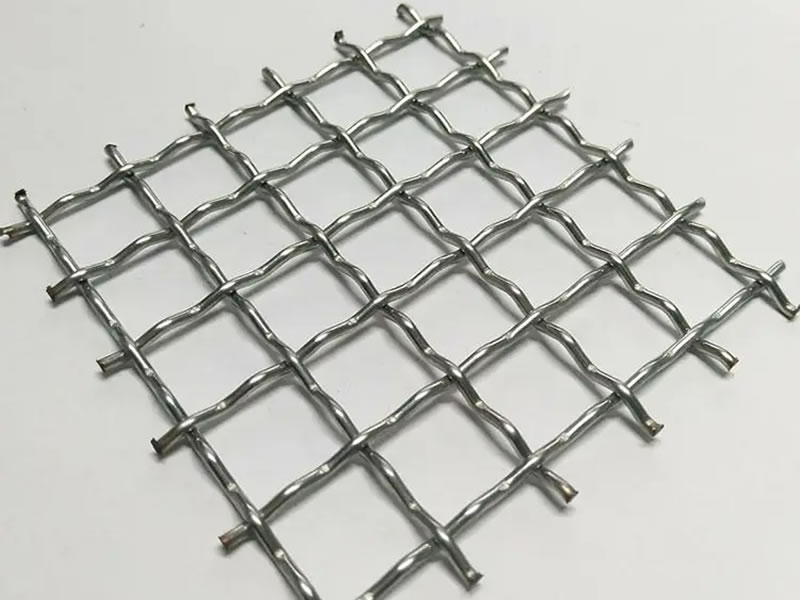

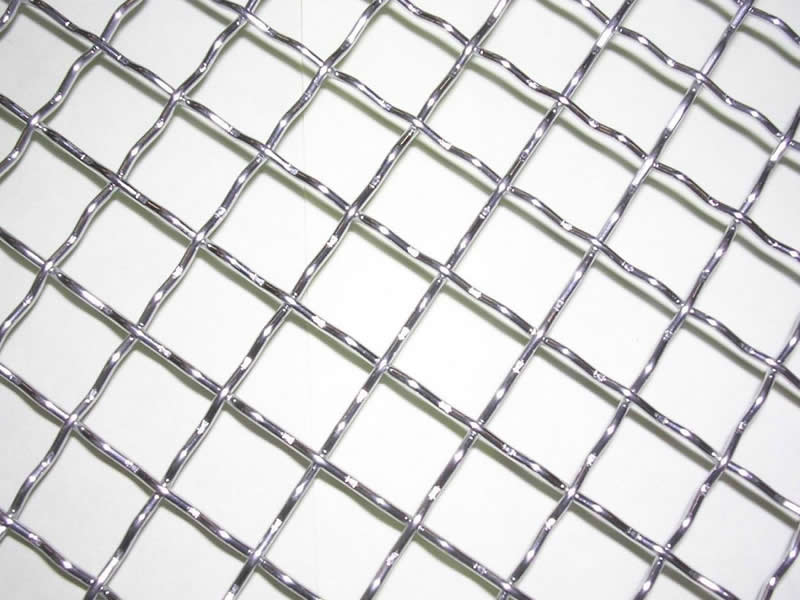

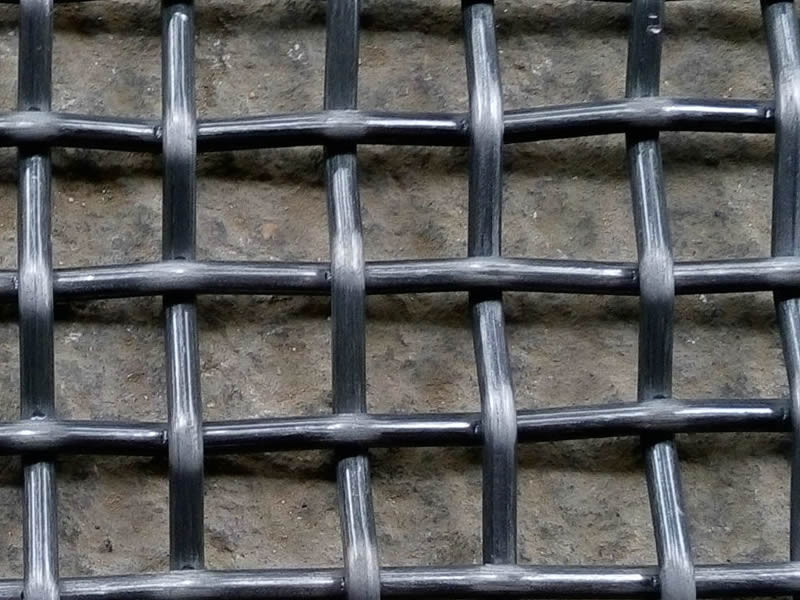

Crimped wire mesh is widely utilized across numerous industries and applications. It is produced by weaving pre-crimped wire strands, which have been shaped into a series of waves or corrugations, allowing the wires to lock together and form the mesh’s distinctive structure. This crimping technique enhances the mesh’s stability, enabling it to maintain its form when subjected to pressure or after being cut into sheets or various shapes.

Material

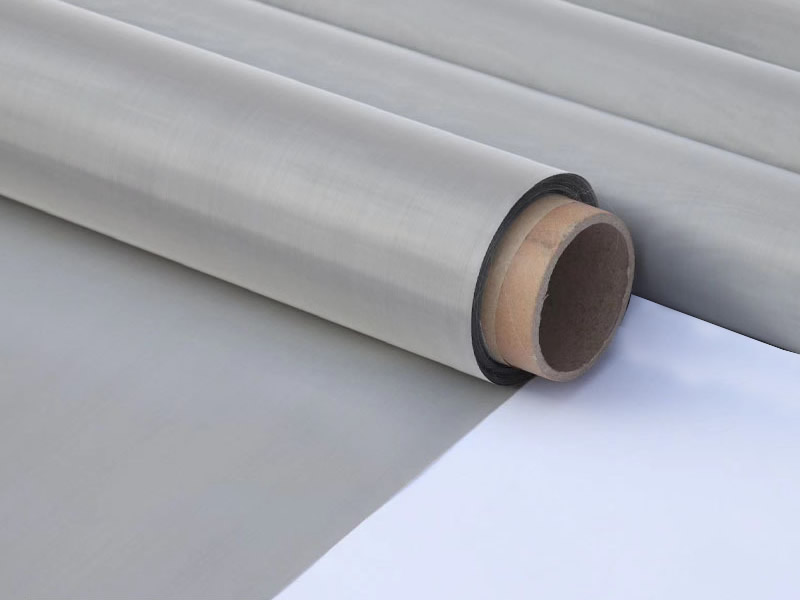

- Stainless Steel: 304 is common and 316 is for tough environments. Both are great for places that need to stay clean, like kitchens and hospitals.

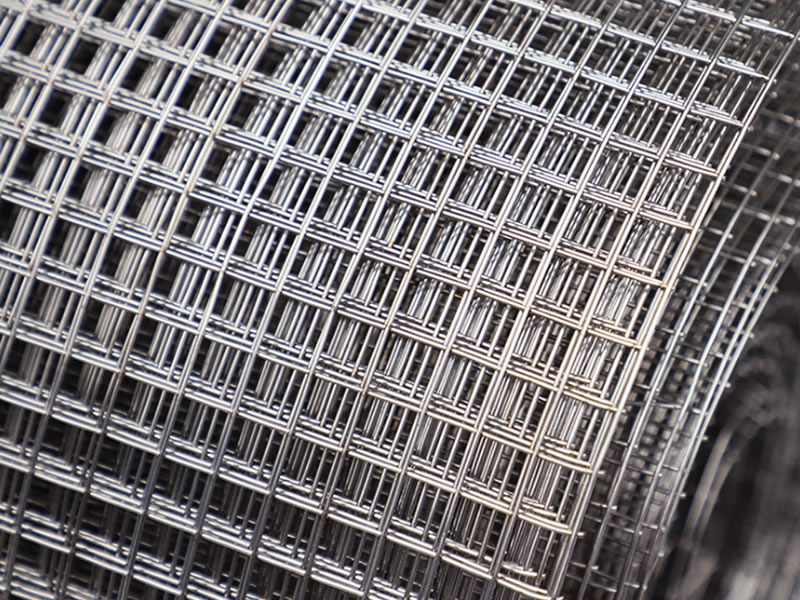

- Carbon Steel: Strong and cheap, good for many industries. It gets a coating to stop rust.

- Galvanized Steel: Comes as hot-dipped for toughness or electro-galvanized for a smooth look.

- Aluminum: Perfect for light, rust-free designs like decorative panels.

- Copper and Brass: Used for their look and germ-fighting properties, ideal for designs and some filters.

- Nickel and Alloys: For the toughest jobs, dealing with intense heat or chemicals. Monel fights chemicals, Inconel resists heat, and Hastelloy handles extreme conditions.

Specifications

- Wire Diameter: Typically ranges from 0.023″ (about 0.5842 mm) to 0.5″ (12.7 mm).Wire gauge indicates the thickness of the wires used in the mesh. Thicker wires offer higher durability and are suitable for heavy-duty applications.

- Mesh Size (Opening Size): Ranges from 0.08″ (approximately 2 mm) to 4″ (about 101.6 mm). Smaller mesh sizes are used for fine filtration, while larger mesh sizes are for more substantial barriers or supports.

- Panel or Sheet Size

Widths: Available from 24″ (610 mm) to 96″ (2438.4 mm).

Lengths: Common lengths range from 24″ (610 mm) to 240″ (6096 mm).

Panels or sheets of crimped wire mesh can be cut to specific sizes, offering flexibility for various applications, from construction reinforcement to decorative uses.

Weave Type

- Plain Crimp: Basic zigzag crimp for stability, great for various screens.

- Lock Crimp: Interlocked crimps for extra strength, ideal for heavy-duty uses.

- Intermediate Crimp: More crimps for greater durability, suitable for fencing and barriers with heavy demands.

- Flat Top Crimp: Smooth top surface for gentle material handling, perfect for food processing.

- Double Crimp: Even crimps ensure stable, uniform mesh, used in design and functional applications.

Strength and Tensile Properties

Depending on the material and wire diameter, crimped wire mesh can exhibit varying degrees of tensile strength, suited to different loads and stresses it will encounter in use.

Classification

- Stainless Steel Crimped Wire Mesh: Excellent rust and corrosion resistance; withstands high temperatures. Ideal for food-related applications. Used in Food processing, chemical manufacturing, architectural facades.

- Galvanized Crimped Wire Mesh: Zinc coating for improved corrosion resistance. More affordable alternative to stainless steel, with good strength. Outdoor fencing, agricultural enclosures, industrial sieving.

- Copper/Brass Crimped Wire Mesh: Antimicrobial; unique aesthetic appeal; conducts heat and electricity well. Patinas over time for a desirable look. Decorative designs, filtering applications, radiator and electronic uses.

- Quarry/Mining Carbon Steel Crimped Wire Mesh: High strength suitable for heavy-duty tasks. Cost-effective solution for industrial use. Quarry and mining operations, construction reinforcement, industrial fencing.